Industrial robots are highly complex machines that are capable of performing a wide variety of manufacturing processes, including some that were formerly thought to be achievable only through the use of human labor. Programming is the initial step that must be taken for a robot in order for fanuc ipendant Spare parts to be able to carry out a specific function. When it comes to programming industrial robots, robotic teach pendants are by far the most common type of device used. Teach pendants are an indispensable part of any robotic system. Welding automobile frames is impossible for a FANUC R-2000ib/165F without the presence of a teach pendant, whereas the fanuc teach pendant is required for this task. AccessoriesAssembling computer keyboards is not something that LR Mate 200id is capable of doing because they do not have the information required to finish each process.

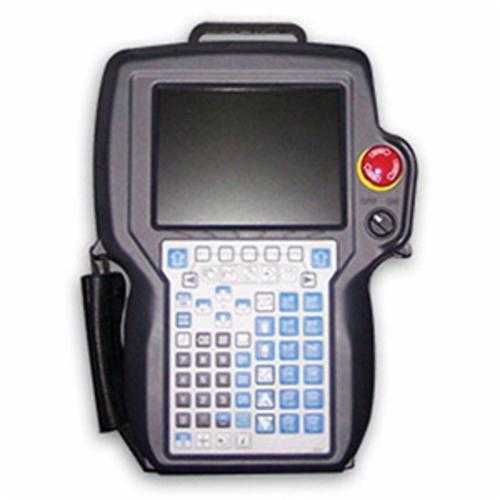

Handheld devices that are either hardwired or wireless can function as robotic teach pendants

When one purchases an industrial robot, the control system will typically come equipped with pendants already attached

They could have a number of buttons or switches, or as is the case with more recent models, they could have a display that was touch-screen based

Additionally, they come equipped with a display that not only shows the commands that the robot is following but also enables the user to edit those commands

In addition to that, the display has the capability of recalling the command history of the robot. A keyboard is utilized by pendants in order to facilitate the input of tasks and simple programming. A large red button, which serves as the emergency stop button of the robotic system, is another characteristic that is frequently found on pendants. It can be utilized in the event that the industrial robot develops a fault, and once activated, it will immediately stop operating, thereby ensuring the safety of any workers or manufacturing equipment in the immediate vicinity of the robot.

The use of robotic teach pendants gives a robot operator the ability to remotely control the motion of the robot as well as to remotely program applications. Pendants allow operators to program robots without requiring them to be physically connected to a terminal in a fixed location. Because of the remote capability, operators are able to safely program or control robots while remaining out of reach of their workspace or potentially dangerous environments. Pendants have a variety of applications, including testing and troubleshooting robotic systems in addition to being used to program and control robots. The capability to put robot systems through testing makes integration much simpler. While having the ability to recall the command history and functions of the robot makes it much easier to troubleshoot, it also makes it much faster to identify problems.

Teach pendants are ideal programming solutions because they are designed to be used for teach and repeat programming, which is ideal for industrial robots because they are best suited for performing tasks that are repetitive. Robot operators can program robots for specific application parameters using this method. These application parameters may include the speed of the robot and its range of motion. Because of the controls that are located on the pendant, an operator is able to communicate with the robot regarding cycle times, velocity, functionality, and any necessary interactions with any additional machinery that is involved.

For the purpose of programming a FANUC M-710ic/50 for a die-casting application, for instance, a teach pendant may be utilized. The pendant will transmit information regarding each step that is necessary in the application process. These steps include loading the die-cast machine with the mold, injecting the mold, and then removing the cast from the machine and the mold once it has cooled. The operator is spared the hazardous conditions of the foundry by using a robot pendant, which enables the operator to safely program the application while working remotely. Teach pendants simplify the programming of a multi-step manufacturing process by allowing the user to input information using their keyboard rather than manually manipulating the robot or coding through a computer. This makes teach pendants an attractive alternative to traditional programming methods.