In the box customization, the customization of Micropiber Jewelry Bag Producer is a very important one and the most widely used.

When customized Microfiber Jewelry Bag Producer, the first consideration we consider must be the material selection of the box and the determination of style style, and it rarely takes into account the inside of the box.

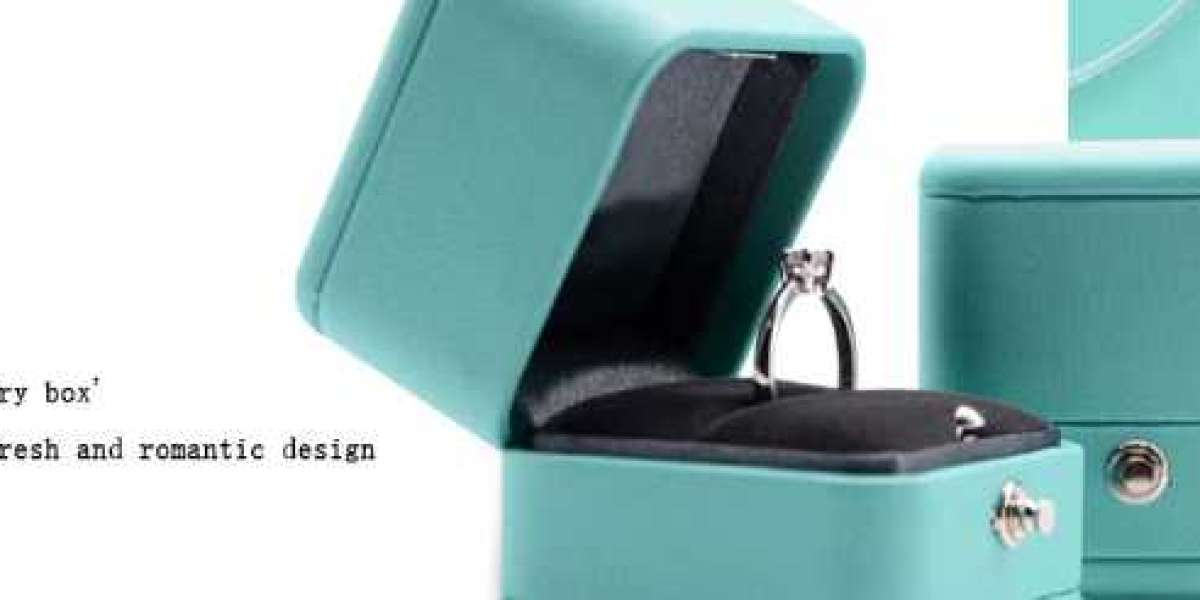

For the box, how to choose a suitable lining is actually a very important link, and its choice will directly affect the grade of the entire packaging box.

For customers, they do not understand the materials and uses of these lining. However, as a professional packaging customization company, we need to know the advantages and disadvantages of various materials lining, and recommend it to customers when appropriate. Essence Next, we will make a general introduction to the common MicroFiber Jewelry Bag Producer lining: cardboard or corrugated paper lining: Most of our common packaging boxes are paper. At the same time Unity of style. The cost of cardboard and corrugated paper is low in cost, environmentally friendly materials, and convenient processing. It is very popular with merchants. At the same time, the paper is easy to set and has good buffering performance. It can protect the entire item during transportation.

Paper lining is often used in electronic product packaging, red wine packaging, etc. EVA lining: EVA is a polyethylene foaming product, which has good elasticity, flexibility, resistance to compression and sealing. The EVA has a smooth appearance, uniform in the bubbles, soft and thick feel, and has a good buffer resistance. EVA lining can be used for groove design, or on the surface of velvet, the groove design can play a role in fixed and displayed products, and the velvet design can make the surface of the lining more soft and shiny. EVA lining is often used for precious and fragile product packaging. Sponge lining: The packaging suitable for high -end products can play a role in buffering and shock absorption. At the same time, the sponge lining also has the division of environmentally friendly sponge lining, anti -static sponge lining and fire -resistant sponge lining. Among them, anti -static sponge lining can protect the product from being damaged by electrical electricity for electronic products and chips. The cost of the sponge is low and easy to process, and it is also one of the lining materials that are very popular with merchants. Plastic lining: I believe that everyone will definitely not be unfamiliar with the lining of plastic materials. Plastic lining is often used in food packaging, such as moon cake gift packaging. Although the plastic lining is not soft or environmentally friendly, it is indeed one of the most used lining materials. Plastic inner lining stability, anti -squeeze, not easy to deform and cost cheap. When using it, it often matches the silk cloth. The silk cloth has a very good gloss, which can increase the texture of the entire gift box. The lining of different materials has different advantages. How to choose the appropriate lining material, I believe everyone has a preliminary judgment. In the process of transportation or handling, the lining can reduce the chance of commodity loss, and at the same time increase the grade of packaging.

microfiber jewelry bag producer https://www.forte-packaging.com/Microfiber-Jewelry-Packaging-Bag.html