Components that make up the bearing system include the bearing itself, the housing that it is housed in, the sealing system, and the main body or casing of a valve. The bearing system also houses the valve. In addition, the main body, also known as the casing, of a valve is a component of the bearing system.

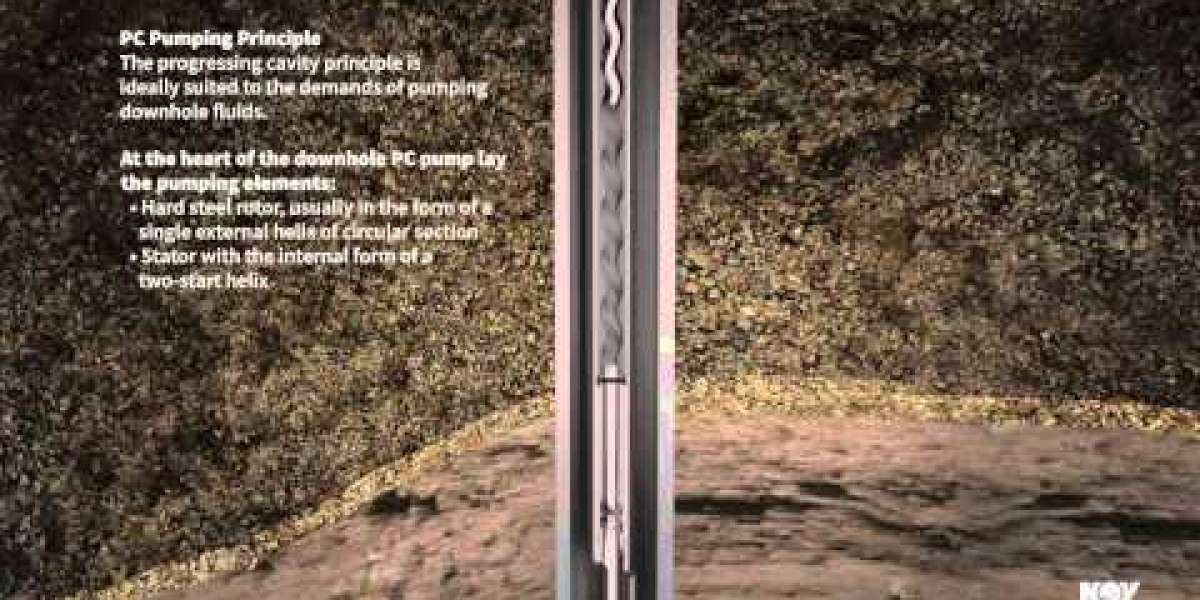

Progressing Cavity Pumping System

Progressing Cavity Pump (PCP) System

Positive Displacement Pump Types

I will make sure that it is always up to date. If you do that, you won't be missing out on any of the updates that I post because you won't be able to access my website. This will take you to the next step in the process. It is made up of a large number of distinct components, parts, and pieces, all of which work together to form the whole. It is possible to draw the conclusion that this particular kind of valve body is the most common type given that the vast majority of the pumps in the processing plant have cast valve bodies. Pump housings can also be customized more easily when they are forged, which is another benefit of the process. Casting is just one of many different processes that can be done; some other options include assembly and forging. There is a diverse selection of casing design options available, each of which is suitable for use in conjunction with a particular pump configuration. Because this helps to reduce the amount of stress that is placed on the body of the pump when the pump has a large radial force, it is common practice for a pump to have a double shell. This is one of the reasons why this practice is common. The photographs that are currently being displayed contain illustrative examples of situations that are comparable to the one that is being discussed here. These examples are included as part of the subject matter of the photographs.

This mechanism, which is in charge of the transfer, is responsible for sending the energy that is produced by the driver to the fluid that is contained within the system. In certain circumstances, the object in question could be referred to as a blade. It is possible to see the opposite side of the impeller blade. In addition to the most remarkable levels of productivity, netzsch spare parts also provides the highest possible levels of performance, which in turn allows for the highest possible levels of both productivity and performance. This ring serves as a protective barrier against the wear and tear that can occur as a result of regular use. In addition, there is a machined finish on the surface. You should make use of fixed or rigid couplings if the drive and the pump can be perfectly aligned with one another. This ensures that the drive and the pump continue to function as intended.

It is not possible to use it in conjunction with the pumps that are used in the process units because it does not meet the requirements for the vast majority of the pumps that are used in those units, and therefore it is not suitable for those pumps. If the shaft is not aligned in the appropriate manner, it runs the risk of being subjected to increased levels of stress, which could cause it to break. The other primary responsibility of the bearing is to ensure that it can move freely without causing any friction to the environment in which it is located. The other primary duty of the bearing is to ensure that it can move freely without causing any friction to the environment in which it is situated. This is the other primary responsibility of the bearing. Because a malfunction in the pump can be caused by improperly selecting the bearing, it is one of the most important components of the device. This makes it one of the most important components overall.

Sealing system In order for the pump to perform the functions for which it was designed in the most efficient manner possible, it is imperative that the pump's sealing system be able to prevent liquid from escaping the pump in any way, shape, or form.

The numerous components that comprise centrifugal pumps will be the primary topic of discussion throughout the entirety of this article. This focus will continue even after those topics have been exhausted. In doing so, you will ensure that you will be among the first to know about any new content that I publish.